Steam Reciprocating Central Heating and Power Mini CHP on Bio-Fuel – Efficient Solution for Green Buildings

A building can be considered green if it’s supplied with energy by environmentally-friendly resources. Steam reciprocating central heating and power mini-plants are the most viable way to produce green energy from the living weight. Such power plants are going to be dwelt on in this article.

Abroad steam-power central heating and power mini-plants (CHP mini-plants) are introduced and successfully exploited in forestry engineering as well as in residential and agricultural sectors. They are particularly organized on the basis of bio-fuel boiler-houses by means of building atop electrical units with steam engines: blade or propeller turbines, steam reciprocating engines. Steam-turbine CHP mini-plants are also used in Russian small energy. With this approach to energy supply we manage to minimize energy waste during its transportation and to gain a reliable source of energy with the heat availability factor of combustible fuel of more than 80%.

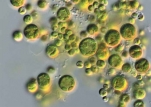

In other countries, Italy for instance, such CHP mini-plants widely use wood waste (wood chips or peel) and pellets (pressurized wood pellets for solid fuel boilers) as fuel. In Russia, however, along with the market of wood pellets developing there appear other promising technologies there. For instance, this refers to the production of the living weight from microalgae. Experts from the Russian National Institute of Rural Electrification (RNIRE) at the Russian Academy of Agricultural Sciences and the Moscow State University of Engineering Ecology (MSUEE) study the possibility to produce gas and liquid types of bio-fuel from these types of material. They are bio-ethanol, bio-diesel fuel as well as mixed compound liquid fuel. It is also possible to run combustion of the living weight of microalgae in a boiler furnace, in steam reciprocating CHP mini-plants in particular.

The technologies of the RNIRE and the MSUEE suggest that microalgae are cultivated in Russia in 2 phases: the first phase refers to nursing stains of microalgae in laboratoryscale photobioreactors, the second phase deals with planting stains of microalgae and nursing them in industrial photobioreactors or pools. The second phase involves monitoring the cultivating environment by means of drones. In future it is worthwhile to work out a way to collect and separate biomass from water by means of natatorial and pumping-filtering elements for subsequent transportation to the processing point.

The economic and environmental effect is reached by partially replacing non-renewable fossil fuels with phytogenic bio-fuel. For instance, one can collect approximately 90 tons of living weight from 1 hectare of water surface. This is 10 times the amount of the biomass that is produced by such crops as rape and soy. Moreover, using microalgae as energy crops will make it possible to minimize the outflow of agricultural goods from the food sector of economics for the sake of biomass production. When studying microalgae researches found out that these plants suppress pathogenic flora, blue-green algae in particular. In fish farms this could serve as an excellent platform to cultivate microalgae in economically idle pools.

Full content of this issue you can read here

The full version of the article can be read in our printed issue, also you can subscribe to the web-version of the magazine

Text by: Ivan Trokhin, engineer, RNIAE of Russian Agricultural Academy

Text by: Ivan Trokhin, engineer, RNIAE of Russian Agricultural Academy